A data-driven digital twin for improved hydrogen storage vessels towards challenges for the energy transition

COFUND-LEAP-RE-D3T4H2S

Europe Horizon – LEAP-RE program:COFUND-LEAP-RE-D3T4H2S

UEFISCDI funding through PN IV: European and International Cooperation; Subprogram: HORIZON EUROPE; Project type: ERANET

Financing contract for project execution no. 11/2024.

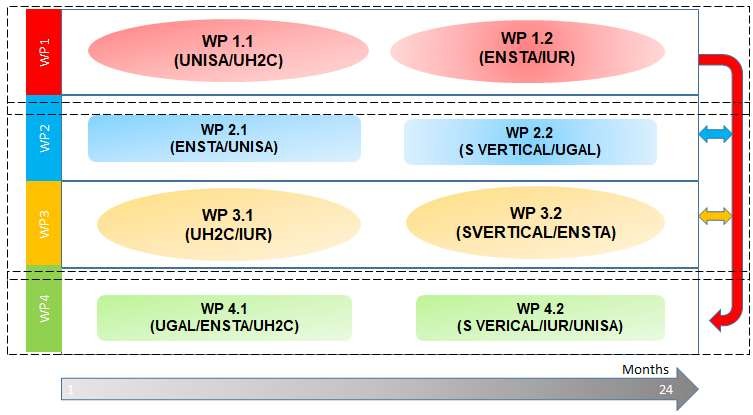

Total Funding amount: 425 000 Euro. Implementation period: 1 September 2023 - 14 February 2026.

UDJG Funding amount: 55 000 Euro (UEFISCDI funding: Euro 42900/Ron 214500).

- "Dunărea de Jos" University of Galați Team: International partners (Consortium):

-

1. Viorel MINZU - Project Director/Coordinator

cv

- S VERTICAL: Medium Entreprise, France (COORDONATOR)

- S VERTICAL: Medium Entreprise, France (COORDONATOR)

-

2. Eugen RUSU - Senior Scientist

cv

- University of South Africa, UNISA

- University of South Africa, UNISA

-

3. Ana CHIROSCA - Postdoctoral researcher

cv

- International University of Rabat, Moroco

- International University of Rabat, Moroco

- 4. Magduța CHIVU – Financiar Responsible - École Nationale Supérieure de Techniques Avancées Bretagne, France - University of Hassan II Casablanca (UH2C)

- UGAL specific research objectives:

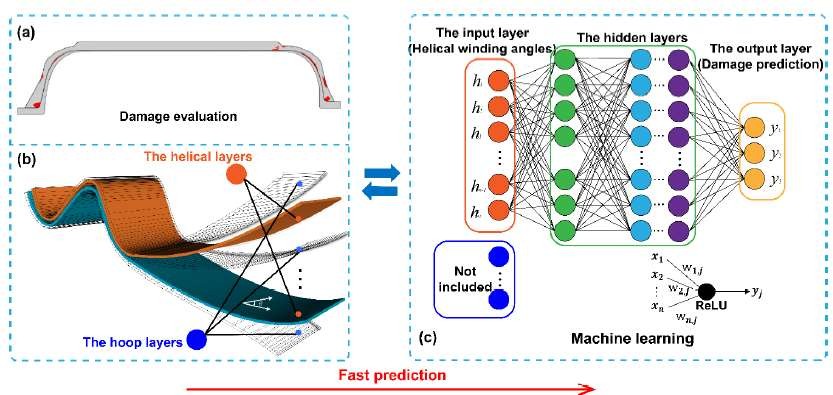

- - Development of Machine Learning models for composite materials used in the manufacture of hydrogen tanks that also allow the analysis of defects in the structure. - Using AI techniques for the optimal design of composite hydrogen tanks.

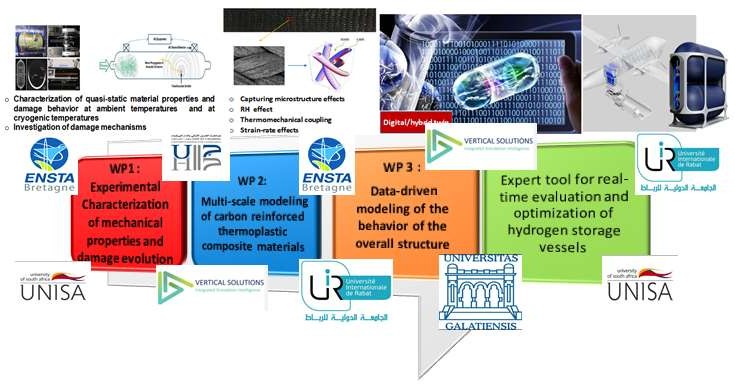

Project Objectives

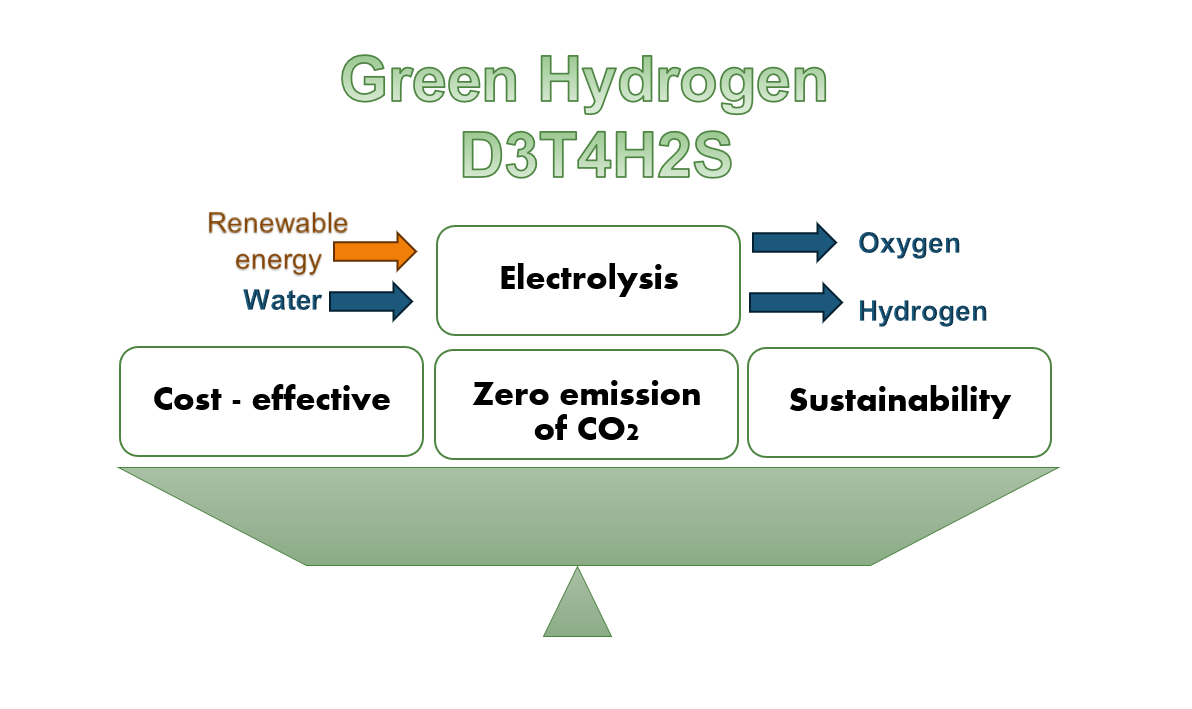

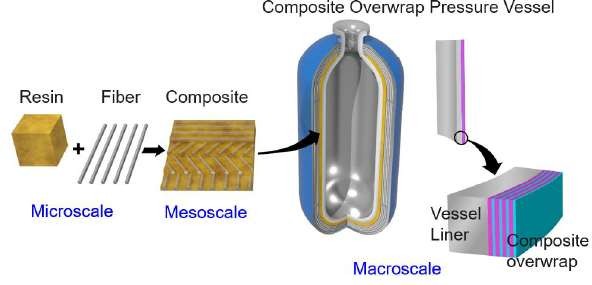

The green hydrogen market will likely grow significantly over the next few years because there is more demand for clean energy sources, and the government is doing more to build a sustainable environment. Hydrogen could be a vital part of a sustainable energy system in the future because it can help get carbon out of the transportation sector. Material science and artificial intelligence (AI) discoveries lead to much new science and technology, such as green hydrogen technologies. These technologies try to meet the challenge of reducing carbon dioxide emissions to help with climate change and the energy crisis. So, it is clear that AI is one way to make the environment more sustainable. The project tackles a global challenge in reaching affordable and clean energy targets by addressing the design of a small-scale proof-of-concept storage vessel in collaboration with SVERTICAL (an industrial partner). The complexity of the topic is strongly related to many aspects involving material sciences, structural thermomechanics, and structure design. The holistic treatment of such aspects exceeds the possibilities of a single research project. Thus, attention will mainly focus on the elaboration of a hybrid carbon fiber reinforced polyamide 12 doped with carbon nanotubes for designing ultralight cryogenic composite vessels (ULCCVs) and on the multi-scale and multi-physical study of its long-term behavior at cryogenic temperatures, its permeability performances, and the issue of damage initiation and propagation. The applicants ambition for the mainstream is to develop ULCCV base materials that provide structural integrity and adequate microcrack resistance against harsh chemicals, thermal, and mechanical loads, as well as the development of an expert tool for better life-cycle management and accurate predictive maintenance, allowing it to reduce costs and maintain a competitive advantage for hydrogen applications. The latter makes sense in digitalization by developing digital and/or hybrid twins dedicated to real-time prediction and correction.

SUMMARY OF THE RESULTS ACHIEVED

Project COFUND-LEAP-RE D3T4H2S

- Development of models for predicting the mechanical behavior of composite materials used in the manufacture of hydrogen transport tanks; - Development of optimization techniques accompanied by related programs that can be used in the optimal design of composite materials used in the manufacture of storage containers.. All research activities carried out by UGAL can be classified, in terms of working method, as "simulated studies." The objective of this study was to develop methods for applying artificial intelligence in the two areas of interest. Prediction models for the mechanical behavior of composite materials were constructed using machine learning algorithms. The models that generally proved to be more accurate in their predictions were those based on neural networks (Regressive Neural Networks). In the case of a family of composite materials that all shared the same characteristic (the same type of carbon fiber), it was found that a single prediction model could be created. This single model has the advantage of requiring less data to train the neural network than the sum of the data required for each material in the family. The second research axis on optimizing the structure of composite materials started from the observation that highly accurate prediction models have been developed that can replace physical models in optimization problems. Their implementation is also very fast. The problem of optimizing the structure of composite laminated materials with 16 layers of different orientations (angles) in relation to the main loading direction was addressed. The problem of finding the optimal structure consists in finding the orientations of the 16 layers that lead to the desired tensile behavior. This is a highly complex computational problem. Therefore, it is necessary to use stochastic algorithms such as metaheuristic algorithms, for example, Particle Swarm Optimization (PSO). The solution is a new method for optimizing the structure of these composite materials through the symbiosis between PSO and machine learning algorithms used to predict mechanical behavior. An optimization structure was proposed, which we called Optimization Framework (OFW), consisting of two modules, one containing an improved version of PSO and the other the model resulting from machine learning. With the help of OFW, two case studies on the optimal structure of composite laminates were solved. The method proved to be accurate and efficient. The results were presented in:

- 5 research reports submitted to the coordinator and in

- 5 articles (including 4 ISI, 3 Q2 level) published in high-visibility specialist journals.

RESULTS OBTAINED IN PHASE 1 - 2024

In the project implementation plan, in the first phase (March - December 2024), we are committed to achieving the following results:

1. Machine-learning (ML) models characterizing the thermo-mechanical behavior of composite materials In activities 1.2 and 1.3, machine-learning (ML) models characterizing the thermo-mechanical behavior of composite materials were developed and validated. These models are described in the study entitled: "Machine Learning models' construction for the load behavior of composite materials in the undamaged zone - Report of UGAL for the project Leap-Re D3T4H2S." [link] This study has been presented in online meetings and submitted to the consortium coordinator, Mourad Nachtane, from S VERTICAL company in order to make it accessible to all D3T4H2S project partners. The developed Machine Learning models have been realized and validated at computer level using MATLAB system. The above study calls upon the multiple programs contained in the archive and well annotated for use. These programs also confer a way of checking ML models. The summarized scientific report addressed to the UEFISCDI is presented in the document "SCIENTIFIC REPORT 2024 annual stage". [link] 2. Publications in journals/proceedings of national/international conferencessProcesses 2024, 12, 991.

https://https://doi.org/10.3390/pr12050991;

Impact Factor 2.8; (WOS SCIE Q2); Citescore: 5.1 (Q2)

Special Issue: Industrial Process Operation State Sensing and Performance Optimization

Published: 13 May 2024

Energies 2024, 17, 5820;

https://https://doi.org/10.3390/en17235820;

Impact Factor 3 (WOS SCIE Q2); Citescore: 6.2 (Q2).

Section A5: Hydrogen Energy

Published: 21 November 2024

RESULTS OBTAINED IN PHASE 2 - 2025

In the project implementation plan, in the second stage (January - December 2025), we are committed to achieving the following results:

1. Scientific reports The results of sub-activities A1–A5 in stage 2 are presented in the following research report:"Implementation aspects of stress-strain characteristics regression models for composite materials" [link] The results of sub-activities A6 - A8 from stage 2 are presented in research report 2:

"Implementation of Machine Learning Models for Composite Materials with the Same Carbon Fiber but Different Matrices" [link] The results of activities A9 - A12 in stage 2 are presented in the following research report 3:

"Contributions to the Optimization of Multilayer Composite Laminate Structures Using Particle Swarm Optimization and Machine Learning" The summarized scientific report addressed to the UEFISCDI is presented in the document "SCIENTIFIC REPORT 2025 annual stage". [link] 2. Publications in journals/proceedings of national/international conferences

Processes 2025, 13, 602.

https://https://doi.org/10.3390/pr13030602;

Impact Factor 2.8; (WOS SCIE Q2); Citescore: 5.1 (Q2)

Special Issue: Application of Artificial Intelligence in Industrial Process Modelling and Optimization

Published: 20 February 2025

Journal of Materials Science and Chemical Engineering 2025, 13, 128-154;

https://https://doi.org/10.4236/msce.2025.13900;

Published: 9 September 2025

RESULTS OBTAINED IN PHASE 3 - 2026

In the third stage (January–February 2026), another study was published on optimizing the structure of composite laminates:

1. Publications in journals/proceedings of national/international conferencesComputers, Materials & Continua 2026, 87(1), 22.

https://doi.org/10.32604/cmc.2026.075619;

Impact Factor 1.7; (WOS); Citescore: 6.1 (Q2)

Special Issue: Machine Learning in the Mechanics of Materials and Structures

Published: 10 February 2026

YEAR 2024

- Minzu, V.; Arama, I.; Rusu, E., 2024, Machine Learning Algorithms that Emulate Controllers based on Particle Swarm Optimization - An Application to a Photobioreactor for Algae Growth Processes 2024, 12, 991. https://doi.org/10.3390/pr12050991; (Q2, IF=2.8);

- Chirosca, A.-M.; Rusu, E.; Minzu, V., 2024, Green Hydrogen—Production and Storage Methods: Current Status and Future Directions Energies 2024, 17, 5820. https://https://doi.org/10.3390/en17235820; (Q2, IF=3.0);

-

A. Studies published in international journals

YEAR 2025

- Brayek, B.E.B.; Sayed, S.;Mînzu*, V, Tarfaoui, M., 2025, Machine Learning Predictions for the Comparative Mechanical Analysis of Composite Laminates with Various Fibers Processes 2025, 13, 602. https://https://doi.org/10.3390/pr13030602; (Q2, IF=2.8);

- Mînzu, V.; Arama, I., 2025, A New Method to Predict the Mechanical Behavior for a Family of Composite Materials Journal of Materials Science and Chemical Engineering, 2025, 13, 128-154. https://https://doi.org/10.4236/msce.2025.13900; B. Studies presented and published in the proceedings of international conferences

-

A. Studies published in international journals

Three articles were accepted for presentation, with topics related to the D3T4H2S project, in December, at the international conference. SGEM International Scientific Conferences on Earth & Planetary Science, Extended Scientific Sessions GREEN SCIENCES FOR GREEN LIFE. Schönbrunn Palace, Vienna 03 - 06 December 2025 , https://sgemviennagreen.org/index.php

- Mihalcea, A.; Chirosca, A-M.; Rusu, L.; A new approach to green hydrogen research – challenges and solutions towards emission reduction and a cleaner maritime transportation

- Chirosca, A-M.; Popa, V-I.; Rusu, E. Assessment of green hydrogen production and potential utilization in the hydrodynamic environment of the Danube

- Bujor, A; Chirosca, A-M.; Gasparotti, C.; Rusu, E. Hybrid energy solutions: hydrogen integration in floating production, storage, and offloading units

YEAR 2026

- Optimal Structure Determination for Composite Laminates Using Particle Swarm Optimization and Machine Learning Computers, Materials & Continua 2026, 87(1), 22. https://doi.org/10.32604/cmc.2026.075619; (WOS, IF=1.7);

-

A. Studies published in international journals

D3T4H2S - Scientific reports for UEFISCDI

D3T4H2S - Certificates

- Viorel Minzu and Eugen Rusu, “Certificate of acceptance for the manuscript (processes-2999578) titled: Machine Learning Algorithms that Emulate Controllers based on Particle Swarm Optimization - An Application to a Photobioreactor for Algae Growth”

- Ana Maria Chirosca, Eugen Rusu and Viorel Minzu, “Certificate of publication for the article titled: Green Hydrogen—Production and Storage Methods: Current Status and Future Directions”

- Baha Eddine Ben Brayek, Sirine Saye, Viorel Minzu and Mostapha Tarfaoui, “Certificate of publication for the article titled: Machine Learning Predictions for the Comparative Mechanical Analysis of Composite Laminates with Various Fibers”

- Viorel Minzu si Iulian Arama, “Certificate of acceptance for the paper (ID: 75619) titled: Optimal Structure Determination for Composite Laminates Using Particle Swarm Optimization and Machine Learning”

D3T4H2S - Announces

- Participation in a conference on a related topic, in Milan, October 8-11, 2024: LEAP-RE Pillar 1 Project Second Call: Mid-term scientific evaluation..

- Participation in a conference on a related topic, in Brussels, October 22, 2025, online, LEAP-RE Annual Forum, "Scientific & Methodological Clusters", "Grid Modeling Cluster" session with the following topics: a) Energy Planning challenges; b) Energy Modeling Approaches; c) Data availability and Data collection techniques.

-

Three articles were accepted for presentation, with topics related to the D3T4H2S project, in December, at the international conference. SGEM International Scientific Conferences on Earth & Planetary Science, Extended Scientific Sessions GREEN SCIENCES FOR GREEN LIFE. Schönbrunn Palace, Vienna 03 - 06 December 2025 ,

https://sgemviennagreen.org/index.php

- Mihalcea, A.; Chirosca, A-M.; Rusu, L.; A new approach to green hydrogen research – challenges and solutions towards emission reduction and a cleaner maritime transportation

- Chirosca, A-M.; Popa, V-I.; Rusu, E. Assessment of green hydrogen production and potential utilization in the hydrodynamic environment of the Danube

- Bujor, A; Chirosca, A-M.; Gasparotti, C.; Rusu, E. Hybrid energy solutions: hydrogen integration in floating production, storage, and offloading units